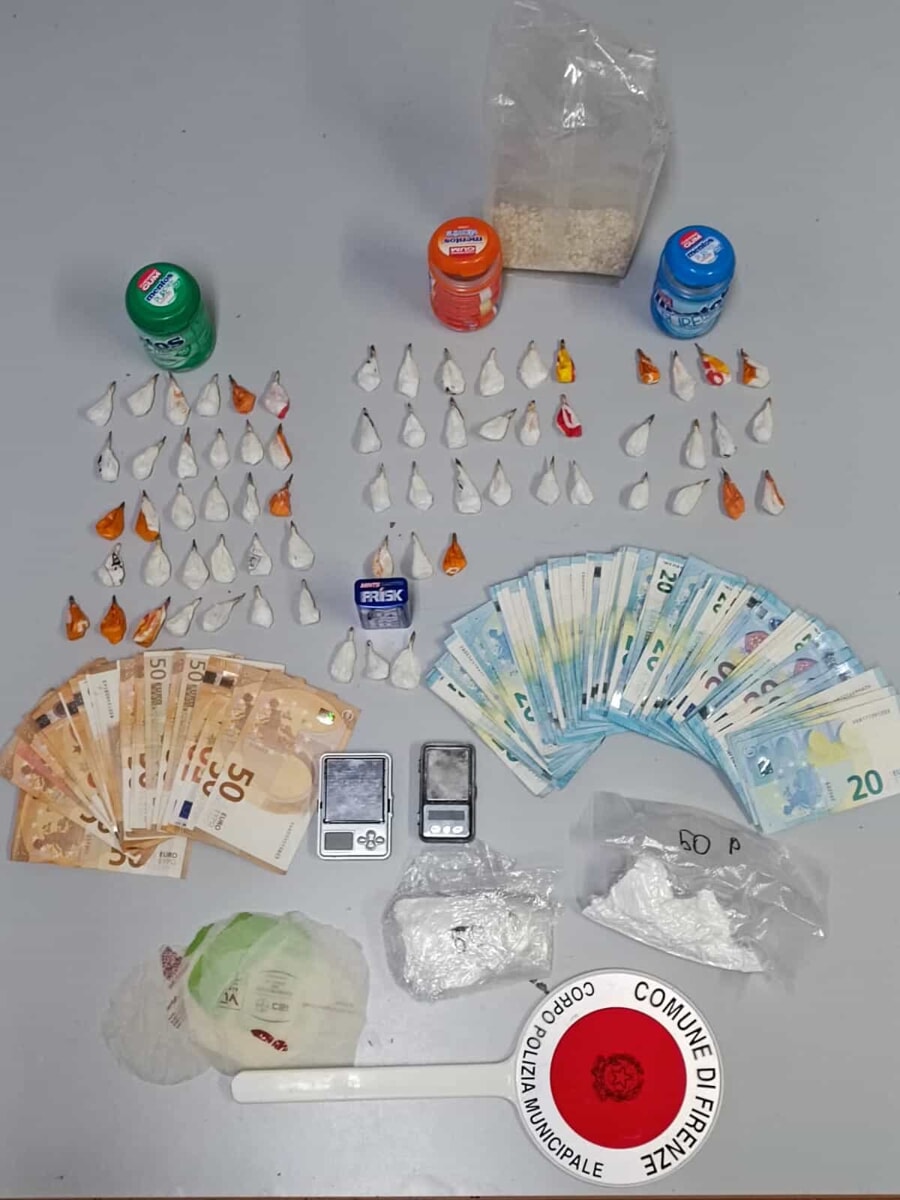

Porta Romana: spacciatore in bici fermato con 150 grammi di cocaina

Un etto e mezzo di cocaina e 2500 in contanti. Spacciava in sella a una bici nella zona di Porta Romana ma il reparto antidroga della polizia municipale l’ha scoperto e arrestato. È successo ieri pomeriggio durante un pattugliamento in centro. Gli agenti della municipale hanno notato un giovane…

Un etto e mezzo di cocaina e 2500 in contanti. Spacciava in sella a una bici nella zona di Porta Romana ma il reparto antidroga della polizia municipale l’ha scoperto e arrestato. È successo ieri pomeriggio durante un pattugliamento in centro. Gli agenti della municipale hanno notato un giovane…